BN138II

20 January, 2025

BN268II

20 January, 2025BN178II

- Shot volume (theoretical): 253,320,363 cm³

- Injection weight (ps): 230,292,329 g

- Clamping force: 1780 kN

- Open stroke: 430 mm

- Space between tie ba (W × H): 465 × 465 mm

- Motor power: 22 kW

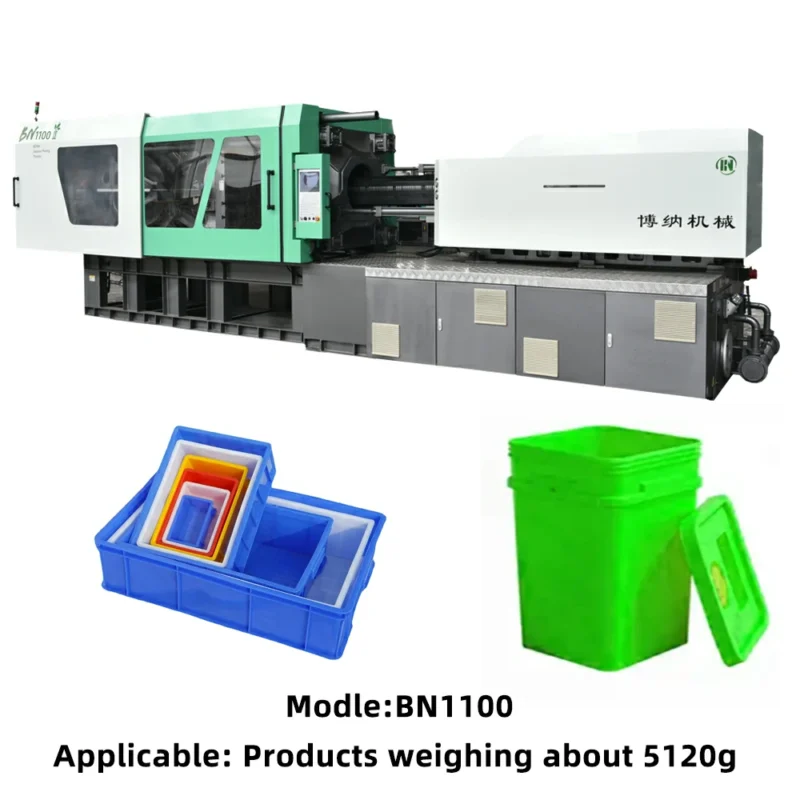

Category: Injection Molding Machines

DETAIL & FEATURE

We produce 100 more types of five series of iniection machines from 50tons

to 3300tons with high quality and stable performance.

FINISHED PRODUCT DISPLAY

We produce 100 more types of five series of iniection machines from 50tons

to 3300tons with high quality and stable performance.

GUARANTEE TERM

We can guarantee all machines are new, different components have different warranties:

2 Years: mechanical of clamping unit and injection unit

1 Years: computer, electric parts in the electric cabinet

6 Months:

a. Easy broken parts like fuse, heater;

b. the screw and barrel.

- Multi-CPU computer control, main cpu adopted with high-performance DSP chips,

Running high speed,integratedperformance well. - 7'TFT-LED screen. physical-entity animation display of machine operation status,

a good man-machine relationship. - Multiple separate power supplies of the operation panel toenable the thunder-proof

design of the: whole syetem. - Stable temperature control precision of士 1°C.

- No use of baEery in data-storage to ensure data safety.

- Parameters of final products recorded for the convenience of quality control.

- Arrewing the transpo~of molds data via flash disk and inconsequence clients

easy data modification.

- Five-piece pivot double toggle clamping unit, integration ofsttong SOlid frame

structure to ensure that the ternplate forcebalanCed, high-speed, and stable. - Solid tempiate for large milling by EUROMAP standard"T"typeslots and drilling

tapping, And has alarge bar space. - Ejector hydraulic cylinder can move flexible lcand the movement

is extremely accurate. - Moving platen with skateboard under the form regulation can take part of vceight

from the mold, reducing the load on the rodand aVoid many malfunction when

using heavy mold.

- High injection pressure and speed.

- Lightweight rugged twin balanced structure, rapid movementguidance system,

support the iniection device. - Ceramic heating coil, and double-layer shields. in addition toreducing energy

consumption, can also reduce the temperature ofthe surrounding environment. - Sliding structure to ensure that drying hopper slides freely, lightand flexible.

- The rear of injection part with three series bearing structure,precise, accurate and

stress is good. - Injection system fully in line with the safety devices to ensureoperator safety and

completely. - Clamping and injection components can match freely according tothe injection

weight. - Screw head and the non-return value imported from japan hottool steel, hardened

by vacuum quenching, with high temperatureresistance, abrasion resistance,

anti-corrosion properties.

1 Are you a trading company or a manufacturer?

We are a manufacturer, we supply the factory price with good quality, welcome to visit !

2How about quality control in your factory?

We have a pre-shipment inspection team, every machine need at least automatic running over 72 hours before shipment.

3 ls there complete machineinclude mould and other auxiliary equipment ?

Yes ,what we are provide is the complete A-Z solution line.

4 Can you help us with the shipment of this machine ?

We have our special shipment company which already cooperate for long time, we will give you the best price, fast delivery.

APPLICATION CASES

Send us a message

| Screw diameter | |

|---|---|

| Screw L/D ratio | |

| Shot volume (theoretical) | |

| Injection weight (ps) | |

| Injection pressure | |

| Injection rate | |

| Clamping force | |

| Open stroke | |

| Space between tie ba (W×H) | |

| Max. Mould height | |

| Ejector force | |

| Ejector stroke | |

| Pump pressure | |

| Motor power | |

| Heating power | |

| Machine dimension (L×W×H) | |

| Machine weight |