BN98-BN1380

23 septembre 2024BN218II

- Shot volume (theoretical): 461 cm³

- Injection weight (ps): 420 g

- Clamping force: 2180 kN

- Open stroke: 490 mm

- Space between tie ba (W × H): 530 × 530 mm

- Motor power: 22 kW

DETAIL & FEATURE

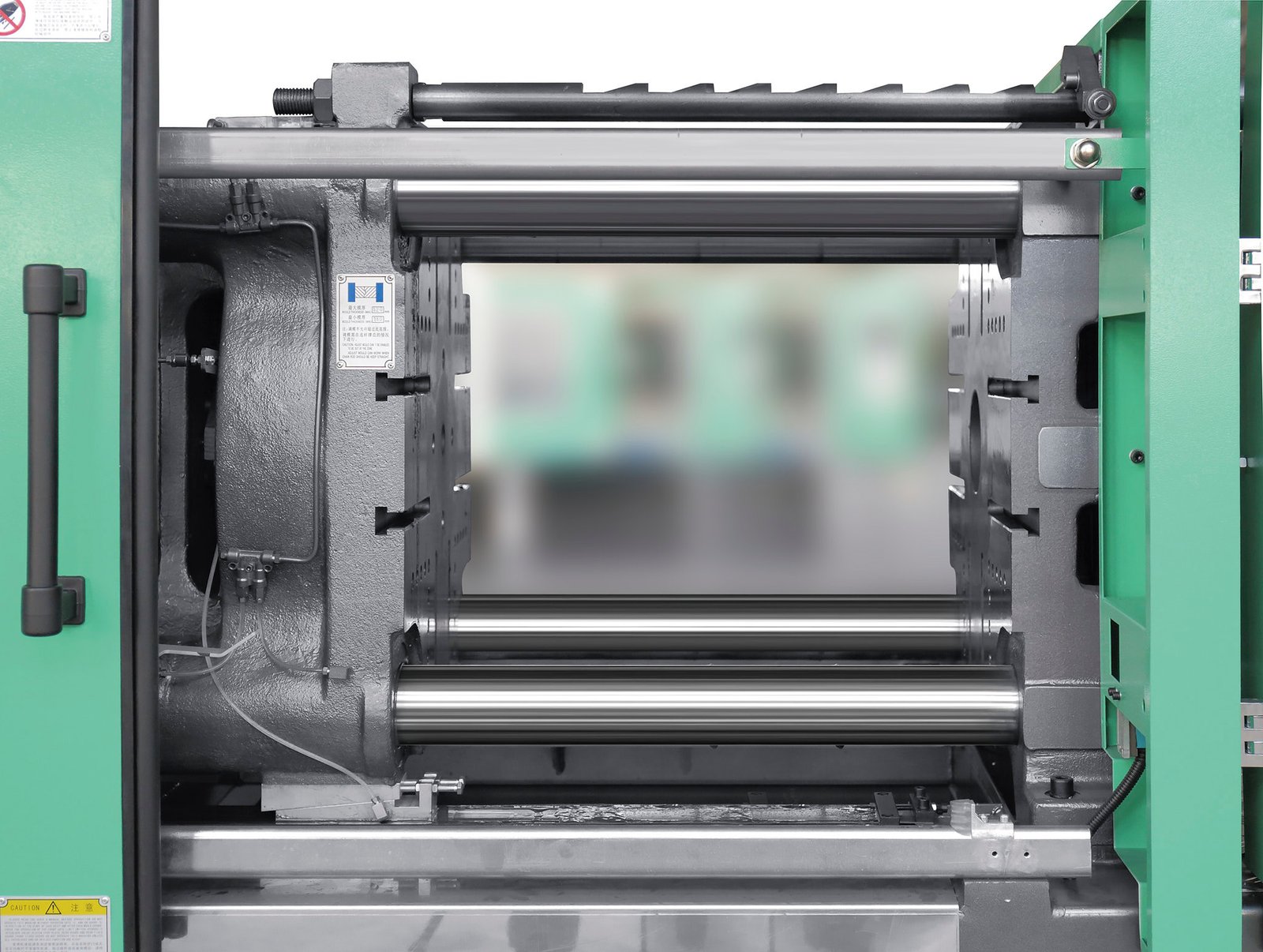

Powerful And Durable Clamping System

Five-piece pivot double toggle clamping unit, integration of sttong SOiid frame structure to ensure that the tern plate force balanced, high-speed, and stable.

Solid tempiate for large milling by EUROMAP standard'T'type slots and drilling tapping. And has a large bar space.

Ejector hydraulic cylinder can move flexible lcand the movement is extremely accurate.

Moving platen with skateboard under the form regulation can take part of vceight from the mold, reducing the load on the rod and aVoid many malfunction when using heavy mold.

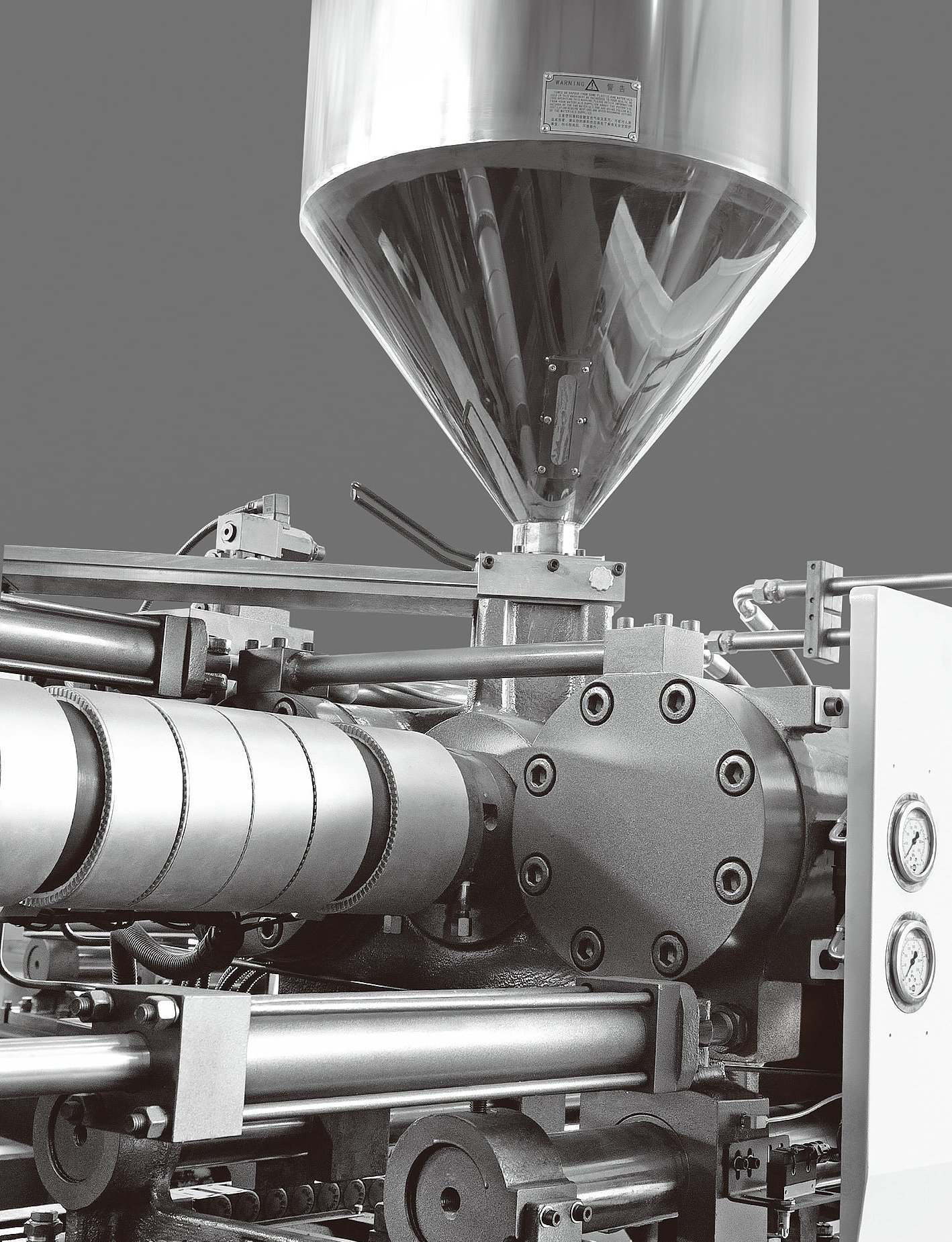

Stable And High Performance of Injection System

High injection pressure and speed.

Lightweight rugged twin balanced structure, rapid movement guidance system, support the injection device.

Ceramic heating coil, and double-layer shields. In addition to reducing energy consumption, can also reduce the temperature of the surrounding environment.

Sliding structure to ensure that drying hopper slides freely, light and flexible.

The rear of injection part with three series bearing structure, precise, accurate and stress is good.

Injection system fully in line with the safety devices to ensure operator safety and completely.

Clamping and injection components can match freely according to the injection weight.

Screw head and the non-return value imported from japan hot tool steel, hardened by vacuum quenching, with high temperature resistance, abrasion resistance, anti一corrosion properties.

Plasticizing egwipped with high precision control.

Anti-hat double-barrel cover prevent operating from injury and reduce energy loss.

Digital Control And Energy Saving of Hydraulic System

Variable pump with high flow to make machine run faster. Compared with the same level of machine can speed up to 20%, and supposing the electrical power, the motor overload significantly can be reduced.Compared with dosing pumps, saving 25%-50%.

With a precise, effective oil filter can ensure the removal of oil svstem contamination and educe machine Maintenance probability.

By using spray tank of intenal oil tank to remove rust and iron for the internal hydraulic system contamination.

In the piping system, together with the large diameter high pressure hose, making the system quieter. lower pressure of oil return line.

Functional Maturation of The Electronic Units

Multi-CPU computer control, main cpu adopted with highperformance DSP chips, Running high speed, integrated performance well.

7' TFT-LED screen. physical-entity animation display of machine operation status, a good man-machine relationship.

Multiple separate power supplies of the operation panel to enable the thunder-proof design of the whole syetem.

Stable temperature control precision of ± 1°C.

No use of baEery in data-storage to ensure data safety.

Parameters of final products recorded for the convenience of quality control.

Arrewing the transpo-of molds data via flash disk and in consequence clients easy data modification.

APPLICATIONS

Phone Case

APPLICATION CASES

Envoyez-nous un message

| Screw diameter | |

|---|---|

| Screw L/D ratio | |

| Shot volume (theoretical) | |

| Injection weight (ps) | |

| Injection pressure | |

| Injection rate | |

| Clamping force | |

| Open stroke | |

| Space between tie ba (W×H) | |

| Max. Mould height | |

| Ejector force | |

| Ejector stroke | |

| Pump pressure | |

| Motor power | |

| Heating power | |

| Machine dimension (L×W×H) | |

| Machine weight |

Video

FAQ

Test:

Here is the FAQs..